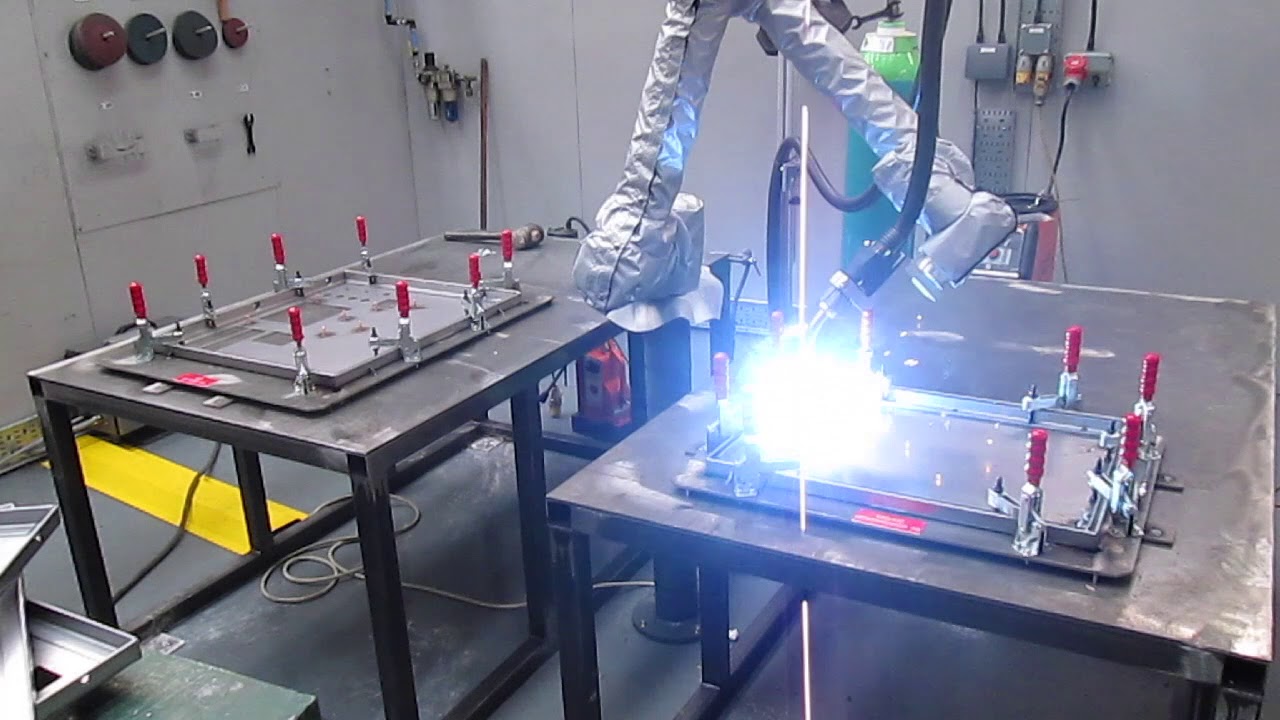

Cobot MIG/MAG Welding

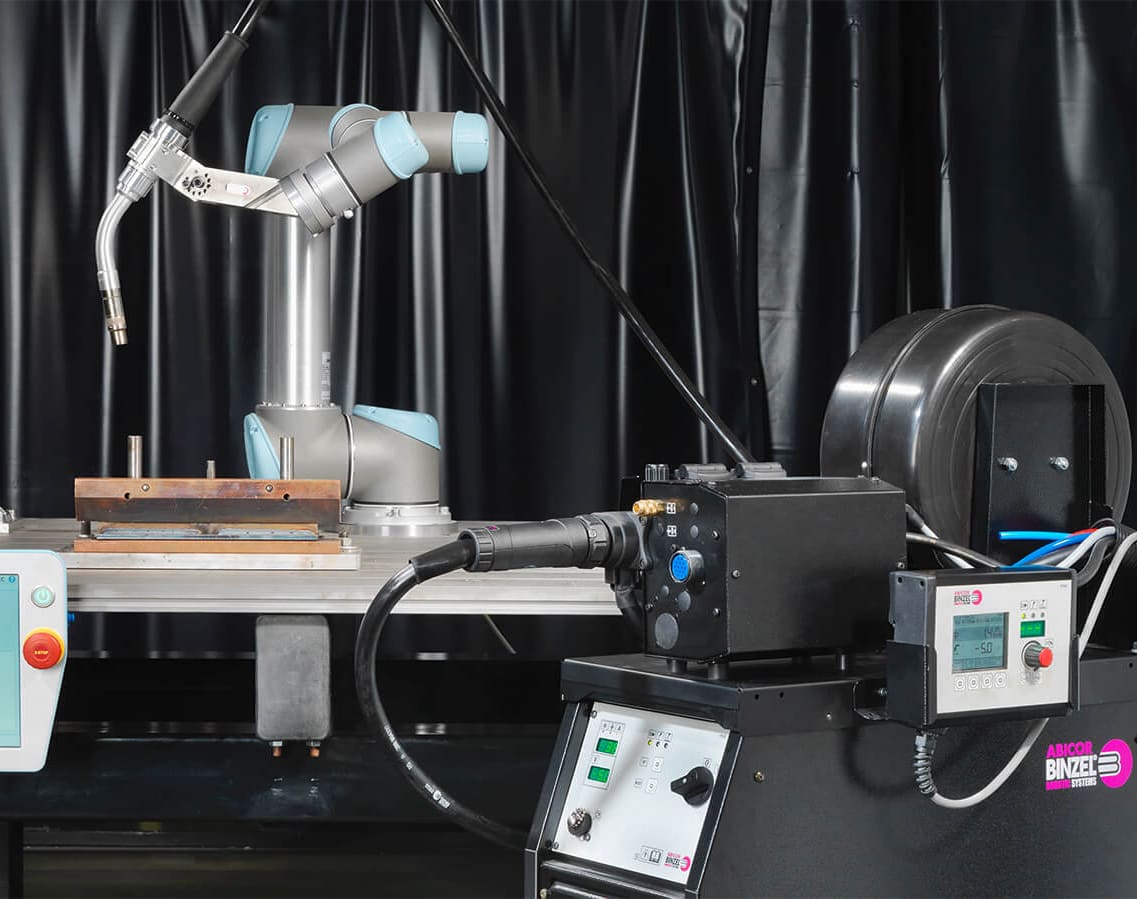

This solution utilizes UR10e robot arm with the cutting-edge technology of robot welding source to automate the MIG welding process. It achieves an incomparable welding quality, speed and efficiency comparing to manual welding.

MAG welding is particularly suitable for welding high-alloy steels, non-ferrous metals like aluminium, nickel, copper and magnesium, and special materials such as titanium.

Specifications:

- UR10e robot, reach: 1,300mm, payload: 10kg

- Power source: iROB Pulse 400A with automatic wire feeding

- Integrated appliance monitoring of gas volume, coolant temperature and flow

- Easy to teach and program to weld new parts